How Predictive Maintenance in IIoT Reduces Downtime: Real-World Impact

Alina Ramanenkava, Growth Marketing Manager

Last updated: August 8, 2025

The Hidden Cost of Downtime

Unplanned downtime is a silent killer in industrial operations. Whether it’s a manufacturing plant grinding to a halt or an energy provider facing turbine failure, unexpected equipment breakdowns disrupt production, jeopardize safety, and drain revenue. According to Deloitte, unplanned downtime costs industrial manufacturers $50 billion annually. For a single factory, a single hour of downtime can cost upwards of $260,000 (McKinsey, 2023).

Enter predictive maintenance (PdM) powered by the Industrial Internet of Things (IIoT). This game-changing approach uses real-time data, IoT sensors, and machine learning to predict equipment failures before they happen, saving millions and keeping operations running smoothly.

In this guide, we’ll explore:

- What predictive maintenance in IIoT means (with clear examples);

- How it transforms manufacturing and energy sectors;

- Two real-world case studies showcasing measurable results;

- The technology stack driving PdM success;

- Future trends and practical implementation tips.

Whether you’re an operations leader, IT strategist, or industrial innovation manager, this article will show you how IIoT-powered PdM reduces downtime, boosts efficiency, and delivers ROI.

What is Predictive Maintenance (PdM)?

Predictive maintenance (PdM) is a data-driven strategy that uses IoT sensors and analytics to forecast equipment failures, enabling proactive repairs to prevent downtime.

Unlike traditional preventive maintenance, which relies on fixed schedules, PdM monitors real-time equipment health — vibration, temperature, pressure, or voltage — to detect anomalies early. When a sensor flags a potential issue, maintenance teams receive alerts to act before a breakdown occurs.

Why PdM matters

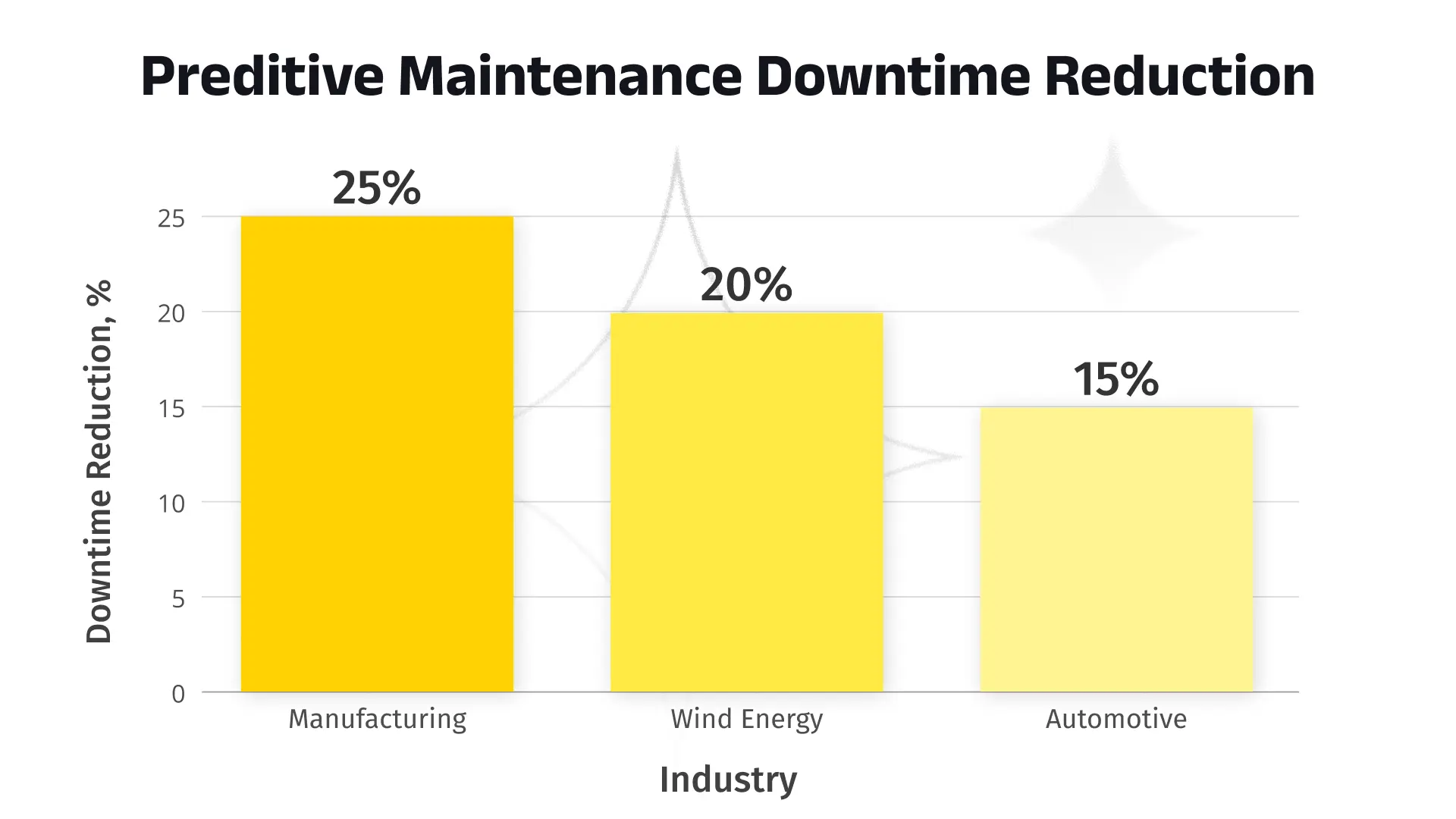

- Saves Time: Reduces unplanned downtime by up to 30% (Gartner, 2024).

- Cuts Costs: Eliminates unnecessary repairs, saving 15–25% on maintenance budgets (McKinsey, 2023).

- Extends Asset Life: Prevents wear and tear, prolonging equipment lifespan.

- Boosts Safety: Minimizes risks from sudden failures.

- Drives Decisions: Provides data for smarter operational planning.

By shifting from reactive to predictive, PdM empowers industries to stay ahead of failures and optimize productivity.

How Industrial IoT (IIoT) Supercharges Predictive Maintenance

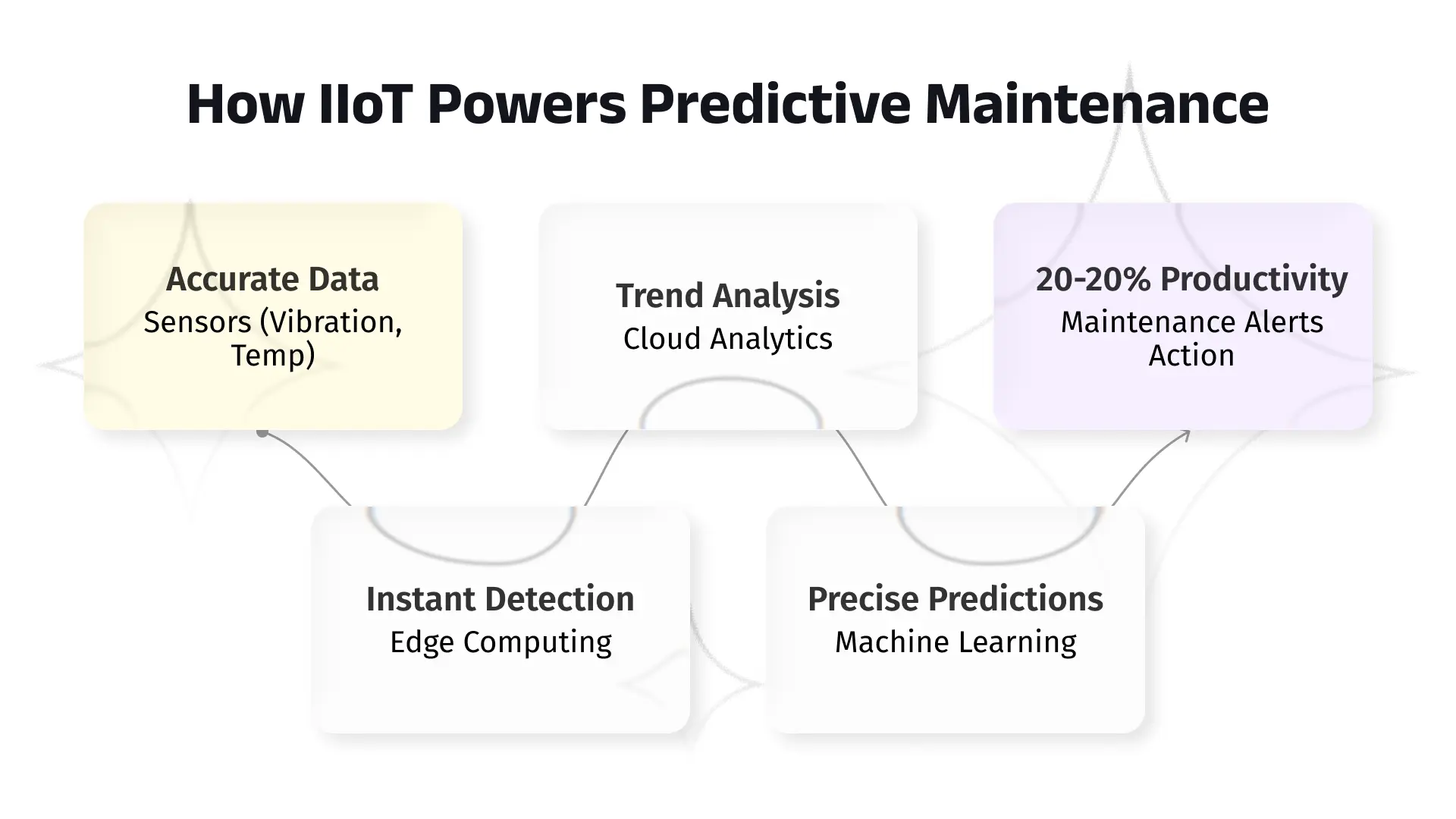

IIoT transforms predictive maintenance by connecting machines, sensors, and analytics into a seamless ecosystem. This connected network collects, processes, and analyzes data in real time, enabling smarter, faster maintenance decisions.

How IIoT enhances PdM

1. Real-Time Monitoring

Sensors embedded in equipment (e.g., motors, turbines) track metrics such as vibration or temperature, allowing issues to be spotted instantly.

Example: A conveyor belt sensor detects unusual vibrations, signaling a potential bearing failure before it halts production.

2. Edge Computing

Data is processed locally at the equipment level, enabling split-second decisions even in remote or low-bandwidth environments.

Example: A wind turbine in a rural area utilizes edge computing to detect overheating without relying on the cloud.

3. Machine Learning (ML)

ML models analyze historical and real-time data to predict failures with up to 90% accuracy (IBM, 2024). Over time, they refine predictions by learning from patterns.

Example: ML detects a recurring temperature spike in a pump, predicting failure weeks in advance.

4. Cloud Integration

Cloud platforms like AWS IoT aggregate data across sites, enabling enterprise-wide insights and scalable PdM strategies.

Example: A global manufacturer monitors 10 factories from a single dashboard.

5. Dashboards and Alerts

Tools like Grafana provide real-time visualizations and automated alerts, empowering teams to act quickly.

Example: A maintenance manager receives a mobile alert about a turbine anomaly, scheduling repairs during a planned shutdown.

PdM + IIoT = Enterprise-Wide Predictive Power

Without IIoT, PdM is limited to single machines. With IIoT, it becomes a scalable, data-driven strategy that aligns maintenance with business goals, slashing downtime and boosting output.

Real-World Results: Predictive Maintenance in Action

Predictive maintenance powered by industrial IoT isn’t just theory — it’s delivering measurable outcomes across industries. Let’s examine two real-world implementations where companies leveraged IIoT and ML to reduce downtime, enhance asset reliability, and boost productivity.

Predictive Maintenance for Manufacturing: 20–30% Productivity Boost

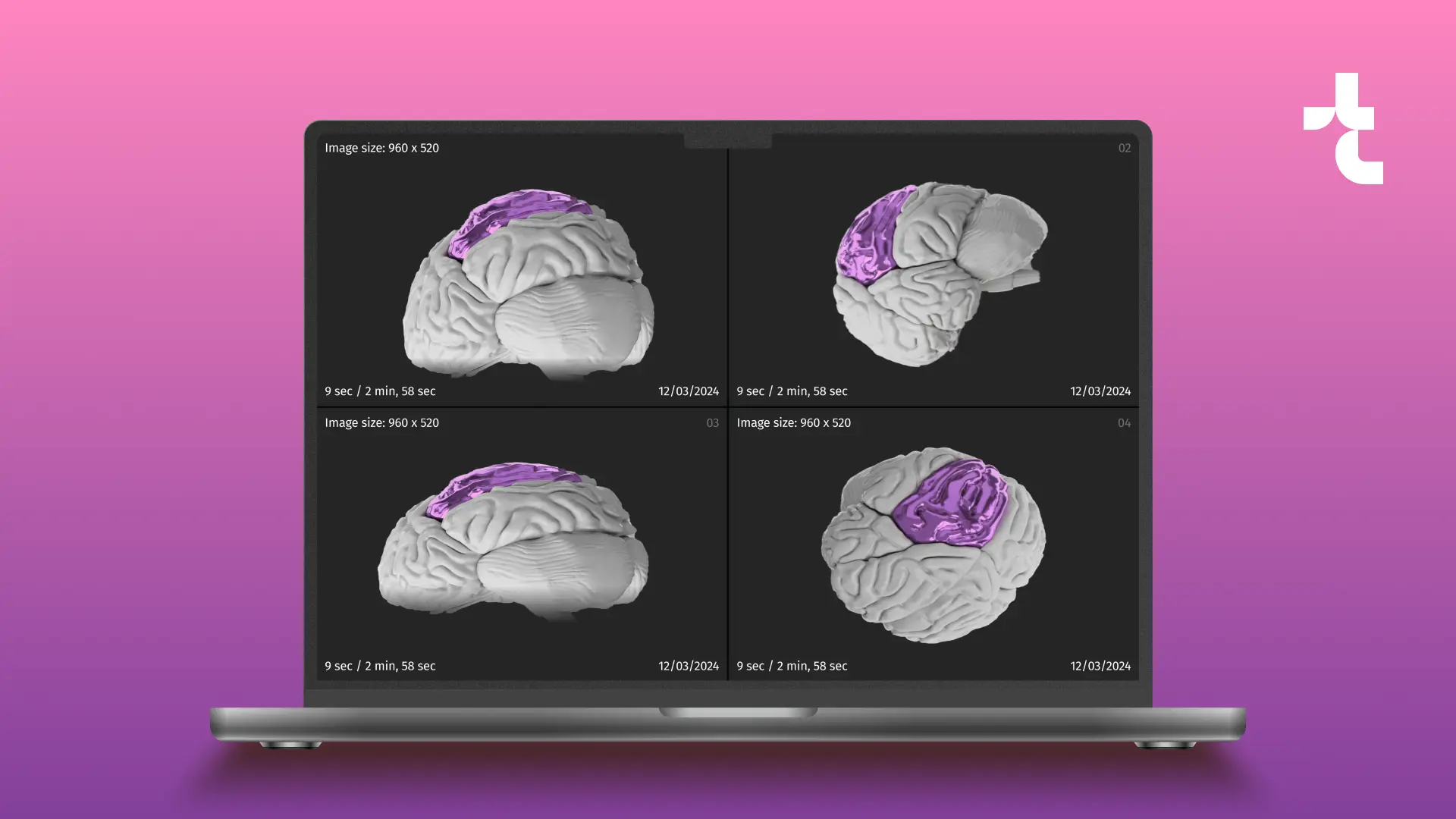

A major EU-based manufacturing company producing industrial machinery partnered with Timspark to develop a custom IIoT platform. The goal is to streamline production management, optimize equipment usage, and prevent costly breakdowns.

Solution overview

- Real-time sensor data collection for temperature, vibration, humidity, and noise;

- Predictive maintenance module analyzing historical maintenance data and sensor patterns;

- Automated alerts on performance anomalies;

- Integration with quality assurance and environmental control modules.

Business impact

- 20–30% increase in production productivity;

- Early detection of anomalies avoids unexpected shutdowns;

- Improved operator decision-making through data visualization and OEE tracking;

- Reduced scrap rate through defect trend analysis.

By combining ML algorithms with sensor monitoring, the platform enabled a shift from reactive to predictive operations — unlocking both efficiency and risk mitigation across factory operations.

Predictive Maintenance for Energy: Preventing 26 Critical Failures

A leading renewable energy provider, managing a large fleet of wind turbines, approached Timspark to build an IoT and ML-based energy management system. Their objective was to reduce system malfunctions, cut maintenance costs, and optimize power output.

Solution overview

- PLCs capturing wind speed, rotation, temperature, vibration, and torque;

- Predictive ML models detecting early signs of wear or overheating;

- Real-time dashboards built with Grafana for turbine status and power output;

- Centralized data lake using AWS for regional sensor data ingestion and analysis.

Business impact

- Up to 6% increase in energy production efficiency;

- 18% reduction in maintenance and repair costs;

- 26 major failures proactively prevented;

- Better planning of energy harvesting and turbine servicing.

The solution empowered operational managers to act before issues became critical, ensuring stable energy delivery and lowering downtime-related costs.

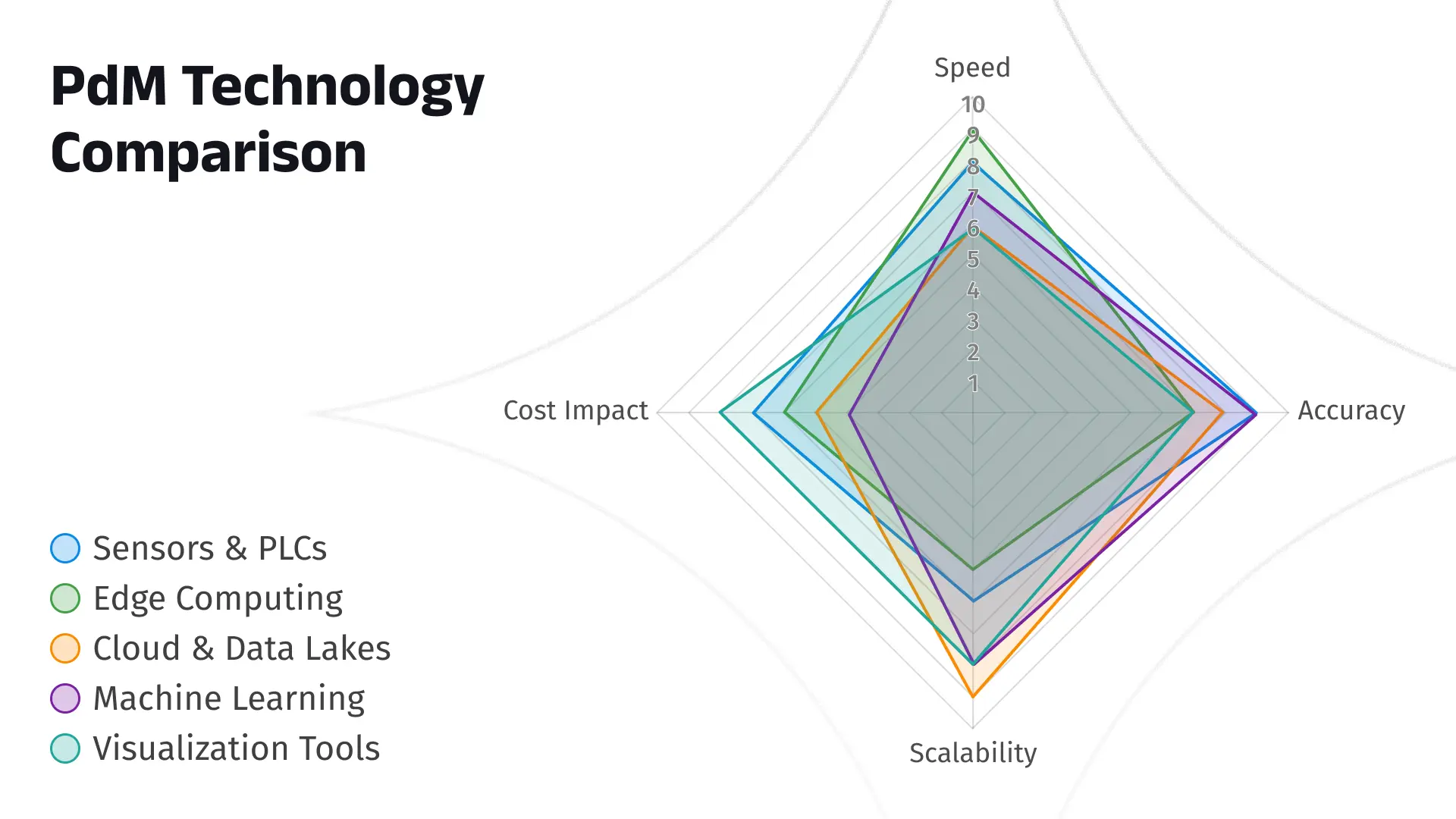

Technologies that Power PdM Success

Technology | What It Does | Business Value |

PLCs & Sensors | Capture real-time metrics (e.g., temperature, vibration, pressure) | Enables early fault detection for proactive maintenance |

Machine Learning | Analyzes historical and live data to predict failures | Forecasts issues with 85–90% accuracy, reducing unplanned downtime (IBM, 2024) |

Dashboards (Grafana) | Visualizes KPIs, alerts, and asset health in real time | Empowers teams with clear, actionable insights for faster decision-making |

Cloud Data Lakes (AWS) | Aggregates data from multiple sites for centralized analysis | Supports scalable, enterprise-wide PdM strategies |

Predictive maintenance relies on a robust technology stack to turn raw data into actionable insights. Here’s how each component drives value:

Why This Stack Matters

- Continuous Monitoring: Sensors ensure no warning signs are missed.

- Scalable Insights: Cloud platforms like Azure IoT enable cross-site analytics.

- Smarter Decisions: ML and dashboards simplify complex data into actionable alerts.

- Agility: Transitions maintenance from reactive to planned, maximizing uptime.

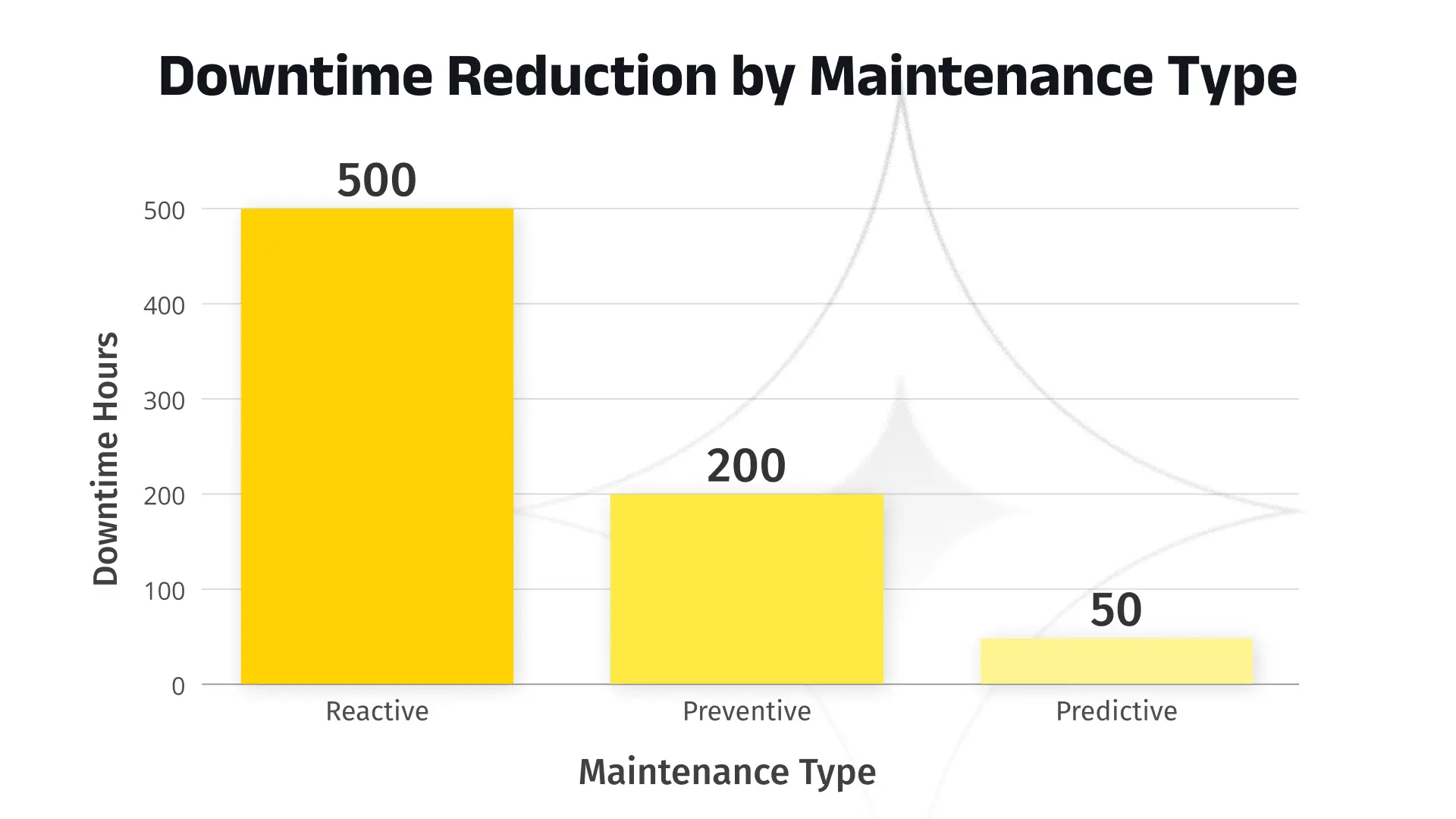

The chart below shows how PdM reduces downtime compared to other maintenance strategies.

Business Benefits of IIoT-powered Predictive Maintenance

PdM with IIoT delivers measurable advantages that transform maintenance into a strategic asset. Here’s how:

- Lower costs: Avoid emergency repairs, saving 15–25% on maintenance budgets.

- Higher uptime: Increase operational availability by up to 10%.

- Longer asset life: Early interventions extend equipment lifespan by 20–40%.

- Proactive planning: Predictable schedules optimize workforce efficiency, reducing overtime.

- Enhanced safety: Continuous monitoring prevents hazardous failures, ensuring compliance.

Maintenance Type | Downtime Impact | Cost Efficiency | Equipment Lifespan | Implementation Complexity |

Predictive Maintenance (PdM) | Low: 20-30% downtime reduction (manufacturing) | High: 18% cost savings (wind energy) | Extends: 26 failures prevented (wind energy) | High: Requires IlqT sensors, analytics platform |

Preventive Maintenance | Moderate: Scheduled stops avoid major issues but may cause unnecessary downtime | Moderate: Better than reactive but lacks real-time optimization | Moderate: Can delay failures, but not avoid all | Medium: Standardized routines, lower tech dependency |

Reactive Maintenance | High: Unplanned failures disrupt production | Low: High emergency repair costs | Shortens: Stress from unexpected failure cycles | Low: No setup needed, but costly over time |

Our successfully delivered IoT projects

By integrating sensors, ML, and cloud analytics, PdM creates a feedback loop for continuous improvement, aligning maintenance with business goals.

Overcoming PdM Implementation Challenges

While PdM offers significant benefits, adoption can face hurdles. Here’s how to address common challenges:

- High initial costs: Phase implementation (e.g., start with critical assets) to spread costs. Most firms see ROI within 12–18 months (McKinsey, 2023).

- Skills gap: Partner with vendors like Timspark for training and support. Upskill staff with data analytics courses.

- Data quality issues: Implement sensor calibration protocols and data validation checks.

These strategies make PdM accessible and effective, paving the way for long-term success.

The Future of Predictive Maintenance

PdM is evolving rapidly, driven by cutting-edge technologies and industry demands. Here are key trends shaping its future:

- Edge AI: Processes data on-device for instant decisions, ideal for remote sites. Example: A mining firm used edge AI to cut downtime by 10% in offline environments.

- Digital Twins: Virtual replicas simulate asset performance, improving prediction accuracy. Example: An oil & gas company used Siemens MindSphere digital twins to reduce maintenance costs by 15%.

- ESG alignment: PdM optimizes energy use and reduces waste, supporting sustainability goals. Example: A manufacturer cut energy consumption by 8% with PdM-driven efficiency.

- Cross-industry growth: PdM is expanding into logistics, utilities, and oil & gas, driven by IoT advancements.

Contact Timspark to tailor a PdM solution for your business.

Frequently Asked Questions (FAQ)

Does predictive maintenance reduce downtime?

Yes, predictive maintenance (PdM) significantly reduces downtime by anticipating equipment failures before they occur. By analyzing real-time data from IIoT sensors, PdM identifies potential issues early, enabling maintenance to be scheduled during planned downtime and minimizing disruptions. For example, case studies demonstrate productivity gains of 20–30% and the prevention of up to 26 critical failures.

How does predictive maintenance benefit from IoT?

IoT, particularly Industrial IoT (IIoT), supercharges PdM by providing real-time data from sensors monitoring vibration, temperature, and pressure. These data streams feed machine learning models that predict failures with high accuracy. IIoT enables edge computing for instant anomaly detection and cloud analytics for long-term trends, making PdM proactive and precise.

How can IoT devices minimize downtime in manufacturing?

IoT devices, such as sensors and PLCs, collect continuous equipment data in manufacturing environments. By integrating with PdM systems, they detect anomalies like unusual vibrations or temperature spikes, triggering alerts for maintenance before breakdowns occur. This approach, as seen in smart factories, streamlines operations and reduces unplanned downtime by 20–30%.

What is the main benefit of predictive maintenance in industrial automation?

The primary benefit of PdM in industrial automation is the reduction of unplanned downtime, which directly enhances production reliability. By utilizing IIoT data and machine learning, PdM optimizes maintenance schedules, reduces costs (e.g., achieving 18% savings in wind energy case studies), and extends equipment lifespan, ensuring seamless automated operations.

What are the advantages and disadvantages of predictive maintenance?

Advantages:

- Reduced downtime: Proactively addresses issues, minimizing production halts.

- Cost savings: Lowers maintenance and repair costs by up to 18–30%.

- Extended equipment life: Prevents wear through timely interventions.

- Improved efficiency: Enhances OEE and productivity in smart factories.

Disadvantages:

- Initial investment: High upfront costs for IIoT sensors and analytics platforms.

- Complexity: Requires skilled personnel to manage data and ML models.

- Data dependency: Effectiveness relies on the quality and volume of sensor data.

Which type of maintenance provides less downtime in production?

Predictive maintenance outperforms other methods like reactive (fix after failure) and preventive (scheduled) maintenance in reducing downtime. PdM uses real-time IIoT data to predict failures, scheduling repairs only when needed, unlike reactive maintenance, which causes significant disruptions, or preventive maintenance, which may lead to unnecessary servicing.

How to avoid machine downtime?

To avoid machine downtime, implement an IIoT-powered PdM system:

Install sensors to monitor equipment health (e.g., vibration, temperature).

Use edge computing for real-time anomaly detection.

Leverage cloud analytics and machine learning to predict failures.

Schedule maintenance based on data-driven insights, not fixed intervals.

Visualize trends with tools like Grafana for proactive decision-making. This approach, as shown in case studies, prevents breakdowns and optimizes production.

How much does an IIoT predictive maintenance system cost?

Costs vary based on scale, industry, and infrastructure. Small setups may start at $10,000–$50,000 for sensors and software, while enterprise-wide systems can exceed $500,000. Ongoing costs include data storage, analytics, and training. For precise estimates, consult a PdM specialist tailored to your operations.

Which industries benefit most from predictive maintenance?

Manufacturing, energy (e.g., wind, oil, and gas), automotive, and aerospace see the highest ROI from PdM. These sectors rely on high-value equipment where downtime is costly. IIoT-driven PdM reduces failures, boosts output (e.g., 6% in energy), and enhances safety across these industries.

Can predictive maintenance integrate with existing systems?

Yes, modern PdM systems are designed to integrate with existing PLCs, SCADA systems, and ERP platforms. IIoT solutions use APIs and standardized protocols to connect with legacy equipment, ensuring seamless adoption in smart factories and industrial automation environments.