Expert QA Outsourcing for Software Testing Services

Delivering high quality software demands focused testing efforts. With Timspark’s end-to-end QA outsourcing services, your development team can focus on innovation while we ensure reliable products through comprehensive testing—from functionality to security.

Timspark has been acknowledged as a Top QA Testing company.

GoodFirms

Top QA Testing Company

GoodFirms

Top QA Testing Company

Types of QA outsourcing testing services we offer

At Timspark, we offer comprehensive outsourcing software testing services designed to meet the specific needs of your software development process. From manual to automated, our services ensure you deliver top-notch software consistently.

Functional testing

Unit testing

We analyze software source code line by line, testing each set of modules individually to ensure optimal performance.

Integration testing

We bring all system modules together to ensure they work flawlessly, delivering robust and reliable functionality for your application.

Regression testing

We thoroughly test your application after updates to ensure all functionalities continue to work as expected, maintaining product quality and reliability.

Boundary testing

By testing edge cases, we identify potential issues, ensuring your application operates correctly under all conditions and delivers a reliable user experience.

Exploratory testing

Our testers use the application like real users, finding issues beyond formal test cases and offering valuable insights for improvements.

Non-functional testing

Performance testing

We measure key performance indicators (KPIs) such as response time, throughput, and resource usage to ensure your application performs optimally under various conditions, ensuring a seamless user experience.

Security testing

We conduct thorough security assessments to ensure your application is protected from data breaches, unauthorized access, and other security risks, ensuring compliance and user safety.

Usability testing

We make sure your software is easy to use and navigate. By testing how smoothly users interact with your app, we identify improvements in design, layout, and functionality to boost user satisfaction and overall performance.

Localization testing

Ensure that your software functions properly in various regions and languages. We check that the content, features, and user interface are adapted to local cultures and regulations, ensuring a smooth experience for users everywhere.

Compliance testing

We evaluate your application against applicable guidelines to ensure it complies with legal, security, and quality regulations, helping you minimize risks and stay compliant in your market.

Compatibility testing

Our cross-platform, multi-device testing outlines how well your solution performs across multiple platforms and devices.

Accessibility testing

Make sure your software is based on accessibility standards and guidelines to identify any obstacles that could impede user interaction.

Automated testing for modern mobile and web solutions

Timspark delivers automated testing across multiple platforms, whether these are mobile or web applications. We ensure quick issue detection and top-tier performance on any device or OS, giving your product the quality it deserves.

Mobile application testing services

Timspark provides mobile testing to ensure your app runs smoothly on all devices and platforms, including iOS, Android, Hybrid, and Cross-platform apps.

Web software testing services

For web software, we ensure your application runs smoothly across various browsers and environments: websites, web applications, SaaS.

Work models we offer

Our talent network is diverse and delivery models are flexible—choose the best QA outsourcing model according to your needs.

Software quality assurance as a service

We thoroughly gather and analyze all project data, and establish streamlined development and QA processes tailored to your needs.

CI/CD for software quality assurance

We help integrate QA solutions for continuous integration and delivery systems, setting precise conditions and triggers for automated testing.

Automated software QA

Based on your project goals and limitations, we define the right automation strategy to speed up testing processes and reduce costs.

QA outsourcing (manual testing & automation testing)

Rather than hiring a full team, opt for an outsourcing solution that delivers high-quality results at a lower cost—bolstering your existing QA team with our engineers.

Dedicated QA team / Independent QA team

QA consulting

Whether you need to get your software analyzed for stability, quality, usability, and compliance with industry standards, Timspark is here to help. We provide expert guidance on various testing types and test approaches to ensure your application is fully prepared for release.

Our QA services process

We implement the right skills of seasoned QA engineers at every stage of the development process, to provide you with comprehensive end-to-end qa testing services.

Planning

We develop a robust project QA strategy and outline the software testing process to ensure all quality assurance measures are in place before development begins.

Design

We create acceptance test cases and scenarios while implementing automated testing to enhance efficiency using advanced testing tools.

Implementation

Our team conducts test runs, tracks defects, and performs regression and performance testing, generating comprehensive reports on the testing progress.

Stabilization

We verify the resolution of fixed defects and conduct regression testing to ensure that modifications maintain software quality.

Delivery

In the final stage, we perform acceptance testing, verify deliverables, and report on final test results to confirm that the software meets all specified requirements.

QA tools & technologies we leverage

We have a whole set of advanced testing tools and testing techniques that guarantee quality in QA outsourcing.

- Mantis, Atlassian JIRA, Elementool, Redmine, MTM, Bugzilla, VersionOne, YouTrack, Rally, QATouch.

- DHC, Advanced rest client, Postman, Swagger, Fiddler, Charles.

- TestLink, JIRA plugins, Quality Control, Qase, Testrail, Clickup.

- Selenium WebDriver (PhantomJS), Selenium IDE, Selenium Builder, SoapUI.

- Jenkins, TeamCity, Vercel, bitbucket, azure, github actions, gitlabCiI, CircleCI.

- SpecFlow, Cucumber, Bellatrix, RobotFramework, custom frameworks, Frameworkium.

- Nmap, OWASP ZAP, Kali Linux.

- Ant/NAnt/CppAnt, Maven, Grunt.

- NUnit, MsTest, Mocha, PyTest.

- Browser specific developer tools.

- Git, SVN, Github.

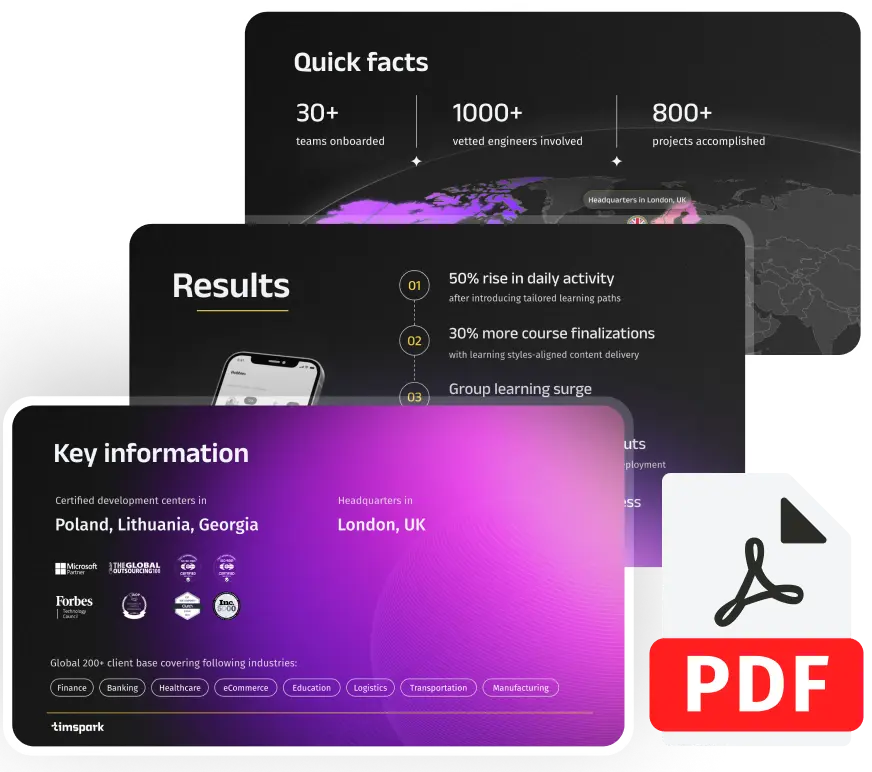

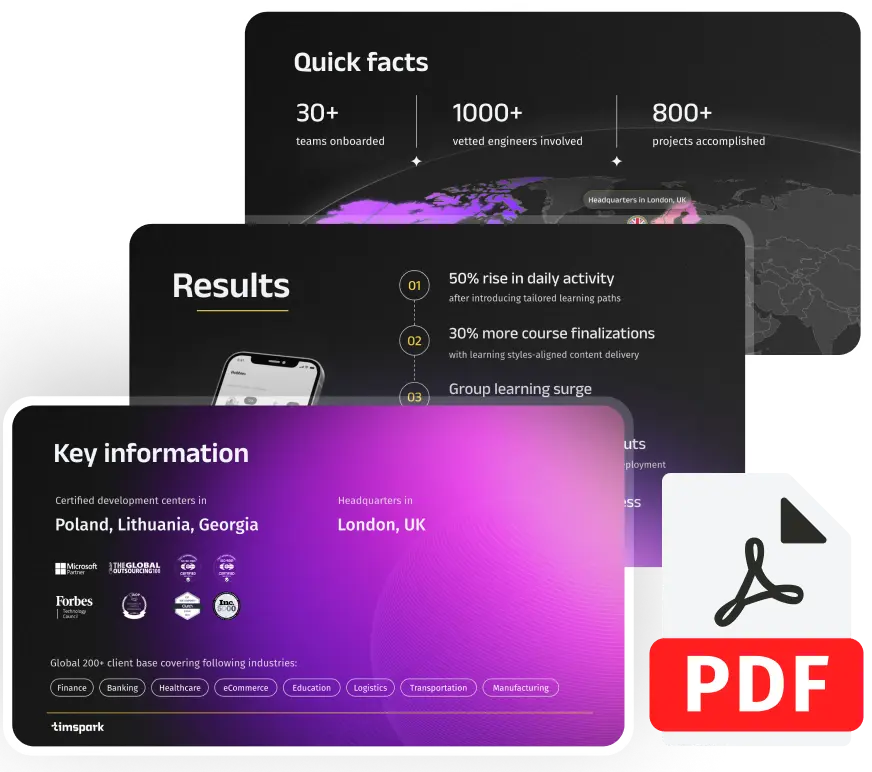

Download our checklist for practical testing insights

Boost performance, quality, and user satisfaction. Get started today and make QA a breeze!

By sending your email you agree to the Privacy Policy and give your permission to process personal data for the purposes specified in the Privacy Terms.

Why QA outsourcing and software testing services by Timspark?

By choosing Timspark among software testing companies, you’re not just opting for QA outsourcing— you’re gaining a strategic partner committed to delivering exceptional quality, efficiency, and smart cost-saving solutions.

Streamlined processes

At Timspark, we streamline your testing process with comprehensive QA coverage, ensuring that your development cycles are smooth and efficient across all your testing projects.

Comprehensive testing solutions

As a premier software testing company, we deliver full-scope testing services tailored to products of any purpose and complexity, guaranteeing that your application meets the highest quality standards.

Cutting-edge QA tech stack

As a testing vendor, Timspark will provide you with a cutting-edge QA tech stack empowering you to utilize the latest tools and technologies.

Smart cost-saving strategies

By optimizing resources, automating where it matters, and identifying issues early, we help you reduce costs throughout the software testing process.

Our successful software testing projects

Related articles

Discover how robust QA services and Quality Driven Development (QDD) minimize risks, reduce costs, enhance performance, and elevate software quality to meet high standards.

Explore how to embrace a strong QA culture for better software outcomes with independent testing services.

Learn how the right testing — whether it’s cross-browser validation, usability checks, or AI algorithm accuracy — ensures your software meets the highest standards for success.

FAQ

Do you still have questions about our QA and testing services? Here are the most frequent questions and answers.

What tools and frameworks do you use for software testing and QA?

At Timspark, we leverage a variety of tools and frameworks to ensure efficient test automation and thorough quality testing. Our tech stack includes Selenium, Appium, Cypress, JIRA, and TestRail, among others. For outsourced QA testing, we ensure seamless integration with your processes, using industry-leading frameworks to maintain high standards and deliver reliable results.

What are the deliverables of QA?

The key deliverables that ensure a well-structured QA process include:

- Test plan: A comprehensive document that outlines the testing scope, objectives, schedule, and required resources.

- Testing strategy: A high-level approach defining the testing framework, tools, and methods to ensure thorough coverage.

- Test cases: Detailed scenarios with steps to validate that every feature performs as intended.

- QA report: A summary of testing outcomes, highlighting issues found, their status, and recommendations for resolution and improvement.

At Timspark, we provide all these deliverables to ensure a seamless and efficient QA process.

Is independent testing better than in-house testing?

First of all, QA outsourcing services offer fresh perspectives, specialized expertise, and access to advanced tools often unavailable in-house. External teams stay focused on quality, delivering more objective results. Plus, outsourcing lets you scale efficiently and cut costs, making it a smart move for many businesses.

What are the must-have QA practices for any project?

- A dedicated testing team to ensure thorough quality checks;

- Every build must be tested to catch issues early and maintain product stability'

- A strong focus on security and compliance with required standards—such as GDPR or HIPAA—is essential.

By leveraging outsourcing software testing, you can access expert teams who specialize in these critical areas, ensuring top-quality results throughout the project.

What is your approach to involving the QA team in an ongoing project?

Our software testers begin by diving deep into your project’s scope, goals, and current status. We then sync seamlessly with your development team, open clear communication channels, and create a smooth, collaborative workflow.

With outsourcing software testing, we quickly align with your processes, provide continuous feedback, and make sure every build is tested to perfection.

Need a reliable QA and testing vendor?

Partner with Timspark for seamless QA outsourcing. Let us handle your software testing needs with precision and expertise, so you can focus on building great products.

What happens next?

An expert contacts you after thoroughly reviewing your requirements.

If necessary, we provide you with a Non-Disclosure Agreement (NDA) and initiate the Discovery phase, ensuring maximum confidentiality and alignment on project objectives.

We provide a project proposal, including estimates, scope analysis, CVs, and more.

Meet our experts!

Viktoryia Markevich

Relationship manager

Samuel Krendel

Head of partnerships